Manufacturing & Quality Data-AI Intelligence

Background

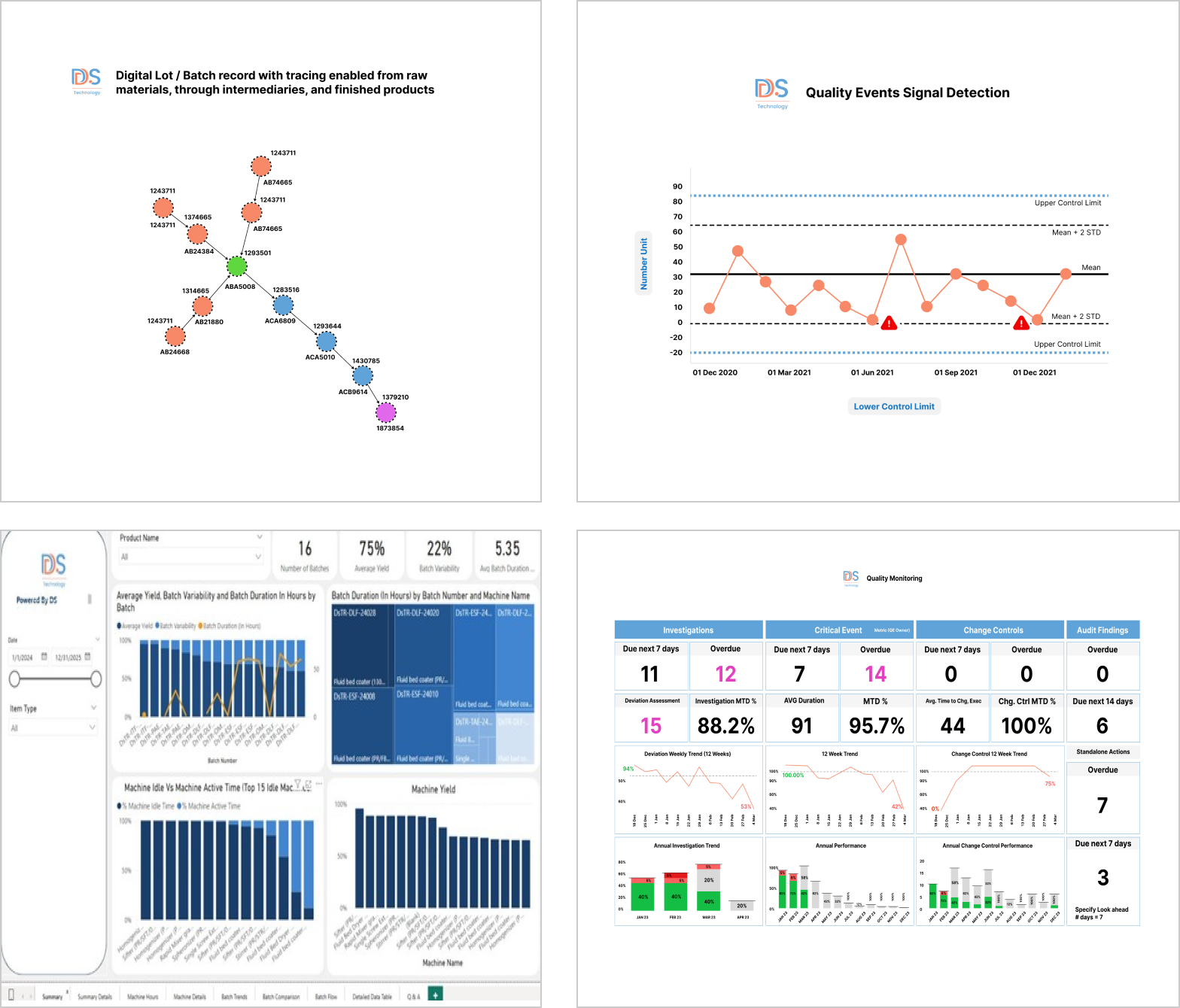

Throughout the manufacturing life cycle, batches and their related components such as raw materials, packaging, finished goods, and quality events move through complex processes, making it hard to trace and visualize the life cycle. The highly complex and inconsistent implementation of data across the commercial manufacturing & Supply chain network makes it expensive to access and link data in meaningful ways for analysis. Limited end-to-end Supply chain visibility with key KPIs such as cycle time, cost, supplier assessment etc. result in delays & unnecessary wastage Understanding several other characteristics like batch yields, lab results, process steps, costs, lead times , supplier assessment and many more for internal and external batches is crucial for network optimization

Manufacturing & Quality Data-AI Intelligence

Functional & Data expertise in Manufacturing Quality, & Supply chain related data domains like ERP, QMS, MES, LIMS learning management etc.

Information & Conceptual data models for harmonizing data across sites, data assets, and systems

Pre-built - reusable Data products & BI dashboards to enable analytics use cases such as Batch Tracking & Risk Monitoring, Quality Control Tower

Generative AI agents and framework trained on internal data - SOPs, CAPAs, Deviations etc.

Benefits

- Enhanced interim data monitoring & early signal detection

- Improved collaboration between internal and external stakeholders

- Structured repository for search across completed studies

- Improved data integrity, reduced data gaps, and efficiency gains with automated capabilities

- A projected cost synergy of 5-7% per study and 30-50% in data infrastructure

- An integrated & harmonized digital replica of ongoing & completed studies